Products of the highest quality

Products and parts from Southbourne Rubber are manufactured, tested and certified to the highest standards

We have a core, well stocked product range which includes O-rings, Grommets, Gaskets, Rubber Seals and Sheet Materials. However, SBR° is experienced and equipped to satisfy orders for Custom Moulding in any shape or elastomeric material required.

Our products are used in some of the most technologically advanced industries in the world. These include Aerospace, Defence (MoD and DoD), Marine and Medical. No matter how big or small your order and what size rubber part you require, we can assist you.

Our teams will be with you at every step: from design and prototype through to production and delivery. Please contact us to discuss your requirements.

Full range of products

Click to read more

XClose

Custom Products

Southbourne Rubber is a specialist in custom moulding and product support. With design assistance, part testing and qualification capabilities, we help bring designs to life ensuring your application has the highest quality and performing elastomeric components.

Click here to find out more about our custom moulding capabilities

Please call +44 (0)23 9225 5180 to discuss your enquiry, get in touch by emailing sales@sbr.aero or complete our online contact form.

Click to read more

XClose

O-Rings

Southbourne Rubber is a globally renowned manufacturer of O-rings, supplying a range of both standard and non-standard sizes and materials across supported industries. Our range of standards supported include both imperial and metric sizes such as BS1806, AS568 and BS4518 as well as international including French R series, German DIN and US Mil specs.

Click here to find out more about O-rings

Please call +44 (0)23 9225 5180 to discuss your enquiry, get in touch by emailing sales@sbr.aero or complete our online contact form.

Click to read more

XClose

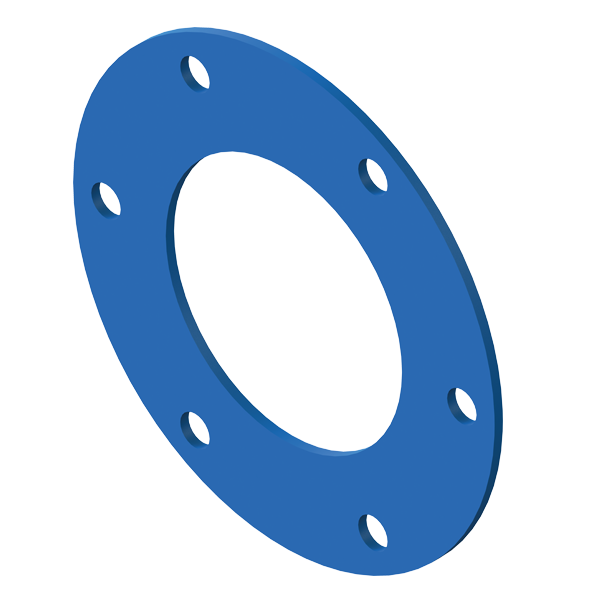

Gaskets

Southbourne Rubber is a specialist manufacture of custom and standard gaskets to the highest quality standards. Utilising a high-speed digital cutter, SBR° have the capability to offer rapid prototyping and mass production through the automated technology. Our gaskets are supplied in a range of materials including solid sheeting, sponge, foam, CNAF, EMI/RFI as well as thermally insulating and conductive materials.

Click here to find out more about gaskets

Please call +44 (0)23 9225 5180 to discuss your enquiry, get in touch by emailing sales@sbr.aero or complete our online contact form.

Click to read more

XClose

EMI / RFI Shielding

SBR° supports a range of EMI/RFI applications across multiple industries, ensuring critical applications are protected from disruption. Our EMI/RFI products are include specially designed gaskets, extrusions, O-rings, pads and many more components.

Please call +44 (0)23 9225 5180 to discuss your enquiry, get in touch by emailing sales@sbr.aero or complete our online contact form.

Click to read more

XClose

Thermal Management

SBR° supports a vast range of thermal management products, including pads, tapes and gap fillers. Each of our thermal management products is capable of delivering performance where the highest possible thermal, dielectric and mechanical properties are required.

Please call +44 (0)23 9225 5180 to discuss your enquiry, get in touch by emailing sales@sbr.aero or complete our online contact form.

Click to read more

XClose

Anti-Vibration

SBR°s selection of anti-vibration products is manufactured from the highest quality materials. Each of our solutions help to specifically reduce excess vibration and shock preventing damage and mitigating transmission of noise. Our range of anti-vibration products stretch form heavy-duty through to small mounts.

Click here to find out more about anti-vibration products

Please call +44 (0)23 9225 5180 to discuss your enquiry, get in touch by emailing sales@sbr.aero or complete our online contact form.

Click to read more

XClose

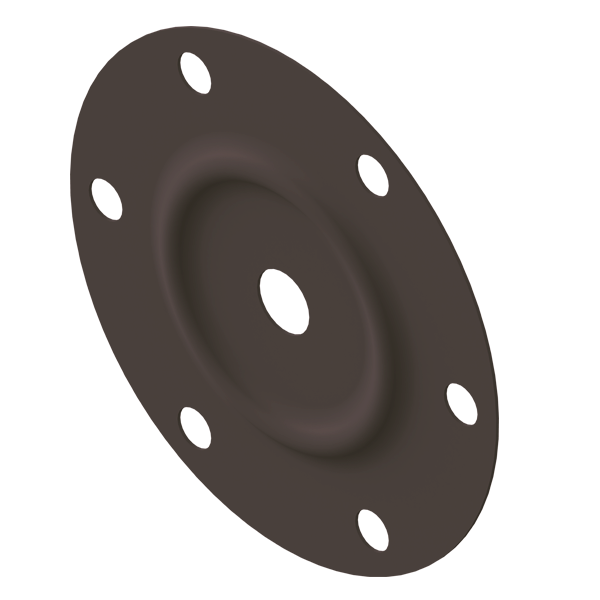

Diaphragms

Rubber diaphragms are a great way to solve sealing problems, preventing unwanted transmission of substances between two places. Our decades of expertise, often in partnership with clients, allows us to design and produce rubber diaphragms unique to a project's requirements.

Please call +44 (0)23 9225 5180 to discuss your enquiry, get in touch by emailing sales@sbr.aero or complete our online contact form.

Click to read more

XClose

Click here to find out more about bellows and gaiters

Bellows & Gaiters

Our bellows and gaiters are produced utilising the latest equipment and technology in order to continually meet customer demands for high-quality products and competitive pricing. Our bellows and gaiters are produced from a range of materials and can offer extensive resistance against dust, grease, oil, UV, water and fuels & acids.

Click here to find out more about bellows and gaitersPlease call +44 (0)23 9225 5180 to discuss your enquiry, get in touch by emailing sales@sbr.aero or complete our online contact form.

Click to read more

XClose

Extrusions

SBR° offers an extensive range of extrusions from a wide range of polymers, sponge and solid. SBR have a wide range of profiles available from common to complex and bespoke, including P-seal, D-seal and cord.

Click here to find out more about extrusions

Please call +44 (0)23 9225 5180 to discuss your enquiry, get in touch by emailing sales@sbr.aero or complete our online contact form.

Click to read more

XClose

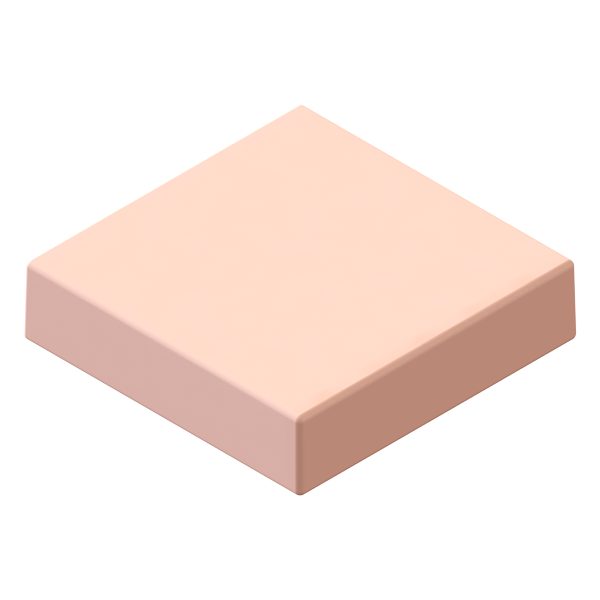

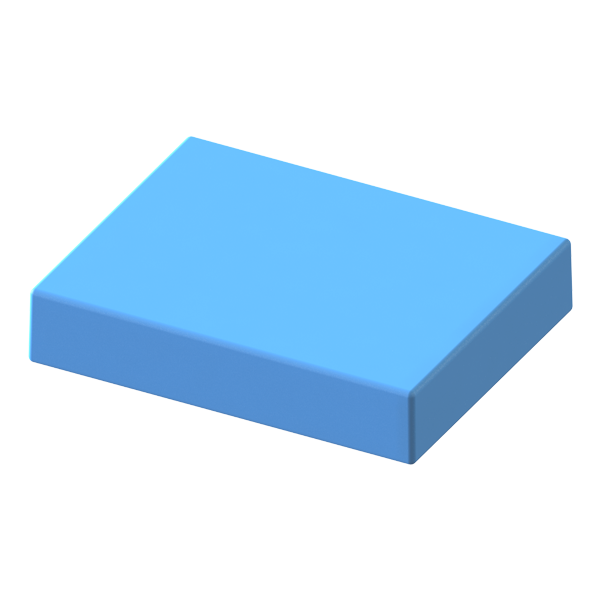

Buffers & Pads

SBR° is a precision manufacturer and supplier of all solid rubber pads. Our pads include standard and non-standard options and are available in a range of applications and sizes to suit. In addition, pads from SBR° are available with either plain or self-adhesive backing.

Please call +44 (0)23 9225 5180 to discuss your enquiry, get in touch by emailing sales@sbr.aero or complete our online contact form.

Find out more

XClose

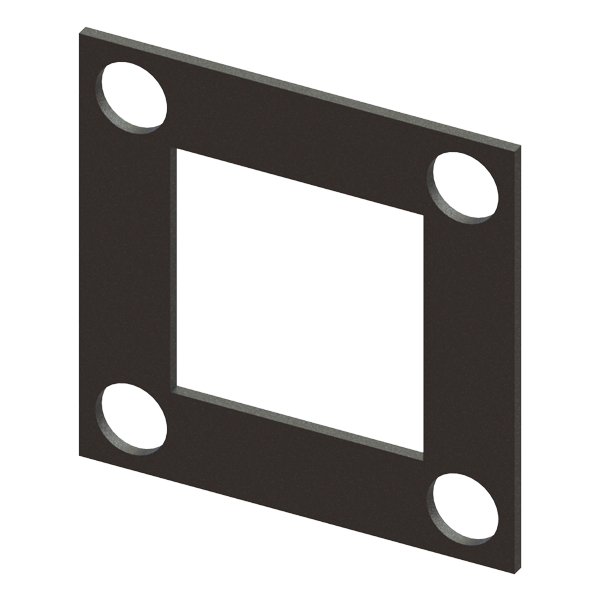

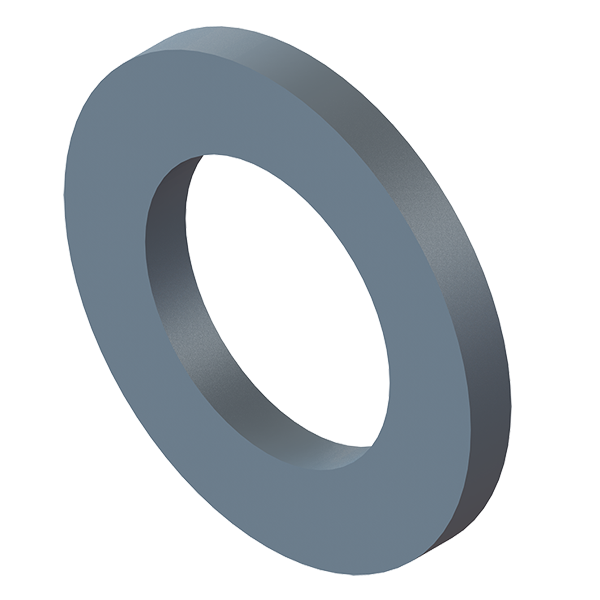

Washers

SBR° offers a variety of customer specific washers. Washers can be supplied in many different sizes, materials and thicknesses. In addition to our custom washer manufacturing, we offer many standard sizes in materials such as solid rubber, sponge, foam and CNAF.

Please call +44 (0)23 9225 5180 to discuss your enquiry, get in touch by emailing sales@sbr.aero or complete our online contact form.

Click to read more

XClose

Rubber Bonding

SBR° has over 50 years’ experience in bonding rubber to metal. We use state of the art machinery, equipment and tooling to provide engineering solutions to your rubber to metal bonding requirements.

Please call +44 (0)23 9225 5180 to discuss your enquiry, get in touch by emailing sales@sbr.aero or complete our online contact form.

Click to read more

XClose

PTFE Components

At SBR° we can offer bespoke PTFE solutions to meet your specification. As experienced suppliers of PTFE products including O-Rings, gaskets and washers, we understand that PTFE can be a great material to use for many applications and has many attractive benefits.

Click here to find out more about PTFE components

Please call +44 (0)23 9225 5180 to discuss your enquiry, get in touch by emailing sales@sbr.aero or complete our online contact form.

Click to read more

XClose

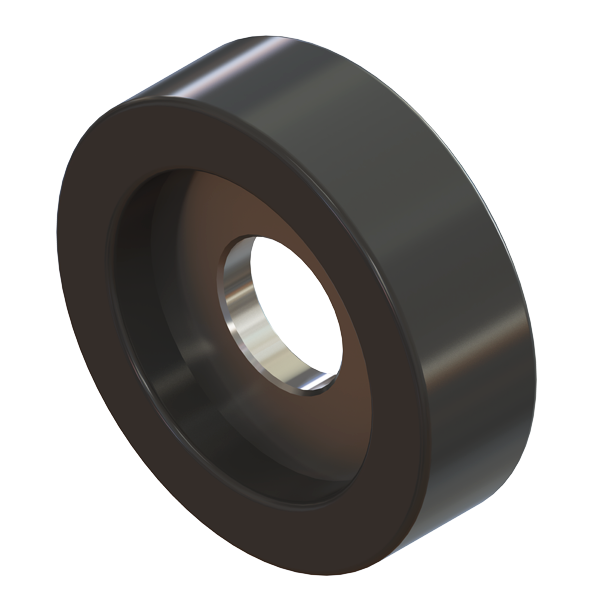

Rotary Shaft Seals

SBR° offers a wide range of rotary shaft seals, including radial oil, rotary as well as V-rings. Our rotary shaft seal solutions are available in both standard and bespoke options and deliver exceptional operational performance with demonstrated low-friction properties as well as wear resistance.

Please call +44 (0)23 9225 5180 to discuss your enquiry, get in touch by emailing sales@sbr.aero or complete our online contact form.

Click to read more

XClose

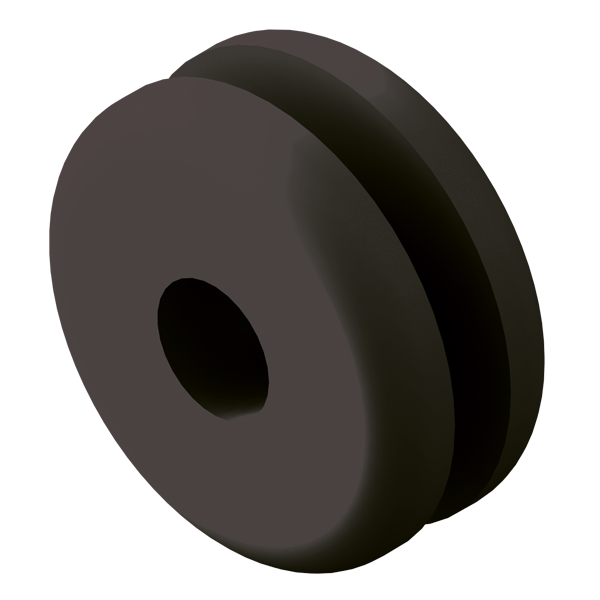

Grommets

SBR° supplies both standard and custom moulded grommets for a broad range of industries and applications from various materials including Neoprene, Nitrile and Silicone. Our standard grommets include the SP93 and SP95 ranges which we have been supporting for over 30 years.

Click here to find out more about grommets

Please call +44 (0)23 9225 5180 to discuss your enquiry, get in touch by emailing sales@sbr.aero or complete our online contact form.

Click to read more

XClose

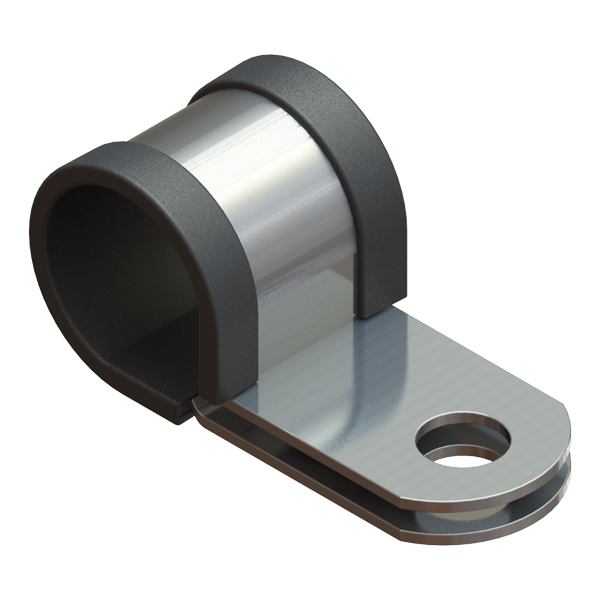

P-Clips

SBR° is a leading P-clip manufacturer and supplier within the aerospace and defence industry offering both the rubber cushion and complete assembly. Our P-clips are available in industry specified materials and are supplied with specified part markings to ensure identification.

Please call +44 (0)23 9225 5180 to discuss your enquiry, get in touch by emailing sales@sbr.aero or complete our online contact form.