Medical grade rubber components for healthcare and life science applications

Medical applications requiring rubber and silicone components have become a specialist area for Southbourne Rubber

Development of new technologies for the medical industry is fast paced. As new treatment solutions are created, technology providers respond to the need with innovative medical device solutions.

Our position as a rubber part manufacturer for the healthcare industry has grown. This is a result of our product quality, cost-effective manufacturing capability, performance and design flexibility. Our material options for our medical grade O-rings, seals and custom components perform excellently in the most demanding environments.

SBR has a forward thinking and agile approach while responding to the developing needs of the markets we serve. Our new life sciences division will be dedicated to the development and supply of our rubber components for medical applications.

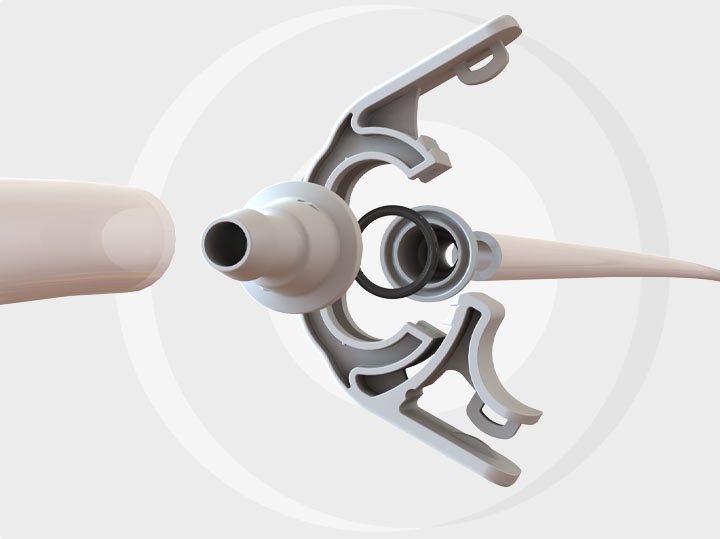

Our medical grade O-rings, seals and tubing provide cost effective solutions for med-tech manufacturers in a variety of life science and medical applications

Our medical grade O-rings, seals and tubing provide cost effective solutions for med-tech manufacturers in a variety of life science and medical applications

applications and benefits of our components

Our life science division components are used across the med-tech industry

From ICU to mainstream wards, the equipment, devices and everyday consumables rely upon rubber and silicone component parts. Our parts portfolio is developed and can be optimised specifically for healthcare and life science applications.

Our range of components combined with our material options mean we have highly flexible capability. We can produce the exact component in the most suitable material. We supply parts for one-off prototypes for the medical device development phase of manufacture. Once a part is finalised, we are then able to fulfil large orders quickly and efficiently to the highest of British standards.

Our medical grade O-rings, gaskets and tubing are cost effective and perform excellently in demanding environments. Key component benefits include:

- Static and slow dynamic applications

- Flexibility - easily designed into many applications

- Available in materials specifically developed for life science applications

- Approvals and standards compliance

- Material traceability

Systems and devices we supply into include cleaning and autoclave systems, drug delivery and fluid transfer. Our medical grade components also support a wide variety of valves, pumps, cylinders and connectors across healthcare settings.

Ventilator Challenge UK - This is a consortium made up of significant UK industrial, technology and engineering businesses. As a supplier into medical applications, SBR are delighted to join other companies to support the fight against Covid 19.

SBR manufacture FDA certified, cleanroom packed rubber parts for medical applications

Our rubber and silicone parts are manufactured from selected materials designed specifically for healthcare environments

Knowledge of rubber formulations, demands of the environment of use and quality controls is essential in this case. SBR have developed an expertise in this area with the support of the other group member companies.

Requirements and regulations for the companies we supply into from the med-tech sector are changing continually. Therefore, we need to ensure every aspect of our production process falls in line.

We supply a range of components with specific attributes including O-rings, fluid seals, gaskets, extrusions, tubing and assembles. Bespoke custom moulding is an area of our manufacturing we have also become recognised for from this industry.

Healthcare devices often requires precision moulded parts to protect delicate instrumentation, protect from dust and other contaminants, fluids and aggressive cleaning agents.

View our product range in more detail ...