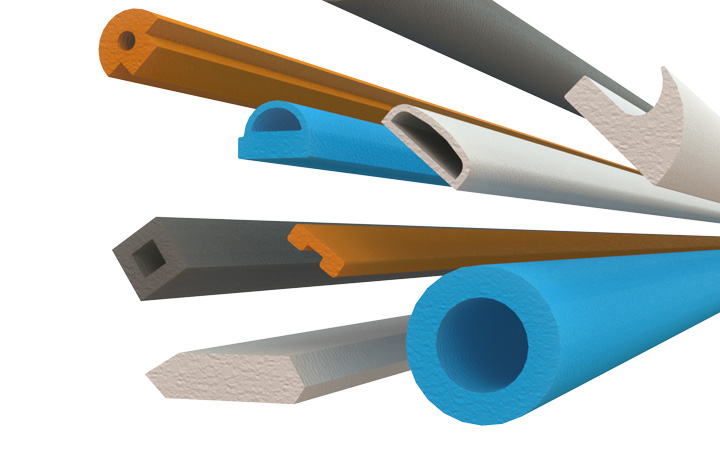

Extrusions

Manufactured in various rubber materials from natural rubber to EPDM, extrusions are parts pushed through a die of the required cross-section under pressure.

The most suitable type of rubber depends on the rubber extrusion’s likely exposure to weathering, temperature, UV and abrasion. Solid Silicone Cord would be used in a situation where O-ring sealing capabilities are required.

Often used for sealing doors, car boots and windows and to control noise and vibrations, our rubber extrusions are available in straight lengths or coils and cut to a length to suit your requirements.

Whether you need silicone rubber or a fluoroelastomer material, we can fulfil and ship your order with accuracy and fast turnaround.

What are Extrusions?

The process of manufacturing extrusions requires an elastomeric material to be pushed through a shaped die.

This cutter is more often manufactured from stainless steel and maintains shape for accurate production of the extrusion.

The shape can of course vary to produce cords or more complicated shaping and cross-section pieces.

To gain an accurate profile, our technicians and design teams will create detailed drawings and produce material samples.